Cooper provides a wide range of force and torque transducers for the automotive industry. We supply directly to the many of the auto giants such as Ford, Honda, Toyota, GM as well as many of their main suppliers and designers, who use Cooper sensors to improve their products and processes. Cooper Instruments has supplied many custom designed sensors and special application-specific designs. Standard off-the-shelf models such as our LGP 310 series Stainless Steel Pancake Load Cells or our model LPM 530 and LFS 270 Miniature Load Cells are popular with machine builders and anywhere a rugged load cell is required. Research and development facilities and precision applications favor our LGP 380/382 series Low Profile Load Cells with their special moment compensated design. The following are just a few examples of Cooper Instruments automotive applications.

- Shock absorber testing

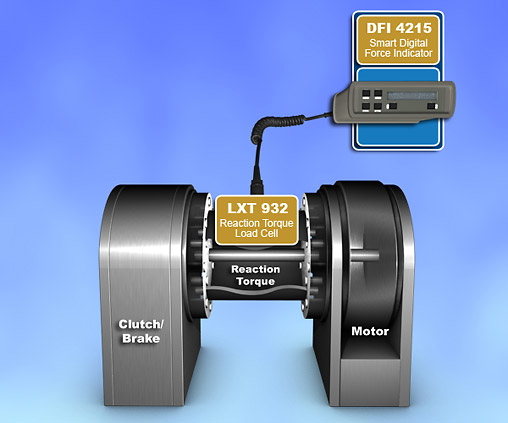

- Engine dynamometer

- Center of gravity

- Valve spring

- Steering torque

- Drivetrain

- Transmission gearbox

- Differential

- Gear mesh

- Spring testing

- Assembly machines

- Bearing press

- Gas tank assembly

- Press to fit

- Durability testing

- Component testing

- Crash test

- Bushing qualification